Date: 1 June 2021

Evaluating production methods to optimise the flow of production is essential, particularly in the current economic climate. This is where the HEGLA team excels, by providing effective solutions at realistic costs.

Those looking to redesign an existing work area or are planning a new site, can be secure with the lifting systems available in the range that provide exceptional safety standards. The tailored HEGLA solutions will improve bottom lines through streamlining production with the most suitable machinery and systems.

Looking at glass handling, across any production facility it has to provide quality guarantees. With this in mind, HEGLA has complete solutions for lifting, with a multi-range of cranes and vacuum lifters that come with either chain hoist or cylinder lift.

A customer’s preferred choice of system will be dependent on the available space and application type, but in all cases the safety of the operator is paramount during production. The HEGLA team always considers product flow and space when creating a floor plan for any factory.

The applications vary across a glass production floor but fundamentally these will be used for handling oversized or heavy glass at Cutting, Toughening and Insulating Glass lines whilst also being utilised for dispatch and multiple applications within glass processing facilities.

Crane System

The crane steel structure, for holding the vacuum lifters, is dependent on height, the space available and are installed to cover the following manufacturing requirements:

- Jib cranes work from a single post requiring minimal floor space area. These are compact and restricted to a 270 degree reach of around 5 – 6m, which is not ideal for all applications but they will fit into limited space.

- Floor mounted post systems can be set out with a matrix of legs situated as required to cover a larger area. These can be used for single or multiple machines and in some instances large dispatch areas where heavy finished products may need trans shipping.

- Another benefit to the HEGLA systems is that it is also possible to mount the systems from existing overhead crane posts and roof sections, which gives a clear floor space but these are much less common

Lifter Systems

HEGLA offers two lifter types.

- Chain Hoist Systems, where lifters are hung from a chain hoist that is mounted onto the overhead structure. The application for this tends to be in restricted height applications but it enables the lifter to move up and down with ease.

- Cylinder Lift Systems, require only a single operator and as the name suggests the up and down movement is controlled by a pneumatic cylinder that has a pre-determined stroke and lift height to a set down point.

For glass processors, the choice will mostly be determined by application type and height availability.

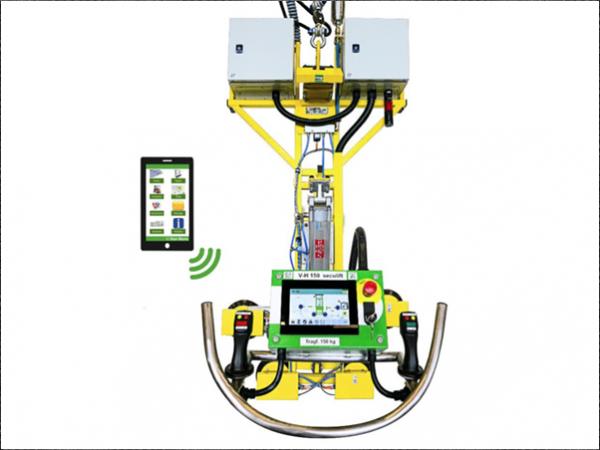

For next generation lifting HEGLA’S V-H 150 system takes glass handling technology to the next level as it lifts, places and manipulates glass on a production floor. The V-H suction device is user-friendly and has exceptionally high safety standards included for day-to-day use on cutting systems, furnaces, and laminating lines.

The V-H 150 system is programmed to prompt operators to complete a function test every eight hours, or at a preferred custom-defined interval. Using a dedicated user interface, prompts are given to initiate each step of the process on screen with results highlighted on completion. Once finished successfully, the machine then begins a countdown for when the next test is due. Should the device fail it will be automatically locked to prevent any accidents.

HEGLA offers a comprehensive range of lifters from simple lift and set down to lift and rotate as well as lift-rotate-tilt, all of which can be used for a wide range of lifting capacity that will suit the application as well as large sheet lifters.

Careful attention to design, layout and installation are all required for a successful project, which are all included as part of the HEGLA service.

Paul Gibbs, Sales and Marketing HEGLA UK comments, “We offer complete and extremely safe solutions that avoid the risk of injury to employees in their working environment.”

Please call Tim Johnson on 0330 124 5759 regarding vacuum lifters and cranes or Paul Gibbs on 07802 655214 to discuss the HEGLA portfolio.

600450

600450

Add new comment