Date: 22 January 2024

Product Marketing Manager, Ashraf Hussein, from GED has written a blog post last year with the title Revolutionize Your IG Quality Assurance with Sparklike Laser Devices. In the blog post Ash highlights how quality assurance in insulating glass (IG) unit manufacturing has new possibilities with Sparklike Laser Integrated and Sparklike Laser Portable devices and multiple benefits to the glass industry. For a comprehensive understanding, we strongly encourage you to read the original blog post here.

Why Invest in Sparklike Laser Technology?

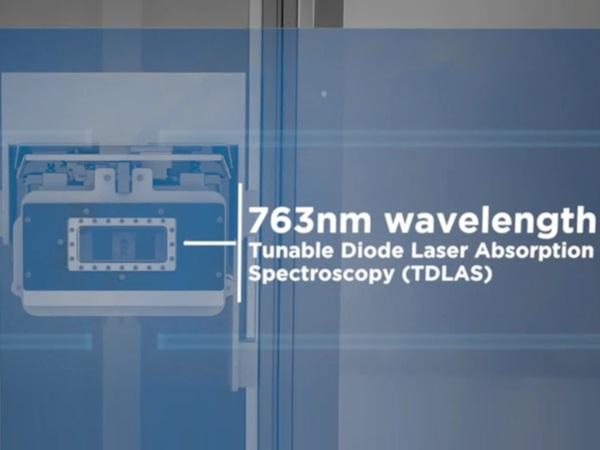

- Advanced Technology for Measuring Insulating Glass Units: Sparklike Laser devices employ laser (TDLAS) technology for non-invasive measurements, accurately gauging gas concentration and glass thickness in IG units with Low-E surfaces and laminates. Devices capabilities extend to Triple Pane Insulating Glass units, including those with 4th surface Low-E.

- Enhance Quality Assurance and Control: By seamlessly incorporating Sparklike devices into your production line, strict control over the quality of your IG units becomes a reality. Real-time measurements provided by Sparklike Laser Integrated enable immediate adjustments, ensuring units are produced to desired specifications and avoiding costly mistakes.

- Risk Mitigation and Cost Savings: Sparklike devices act as guardians, identifying and addressing potential issues before they escalate. Accurate measurements and real-time data significantly reduce the risk of producing defective IG units, leading to substantial cost savings by minimizing the need for remakes and reducing installation costs related to faulty units.

- Industry-Leading Customer Support and Training: GED and Sparklike are committed to providing exceptional customer support and comprehensive training resources, ensuring the seamless integration of their devices into your IG production operations. Continuous improvement and innovation drive their mission, providing you access to the latest advancements in IG fabrication technology.

In conclusion, investing in Sparklike Laser Integrated and Sparklike Laser Portable devices is an investment in the present and future of your company. By enhancing your quality assurance processes, you can significantly reduce the risk of producing defective IG units, saving your business from costly remakes and expenses. Therefore, laser devices offer benefits to the glass industry. To explore the transformative power of Sparklike technology, we invite you to read about our Technology.

GED Integrated Solutions is the official distributor of Sparklike devices in the North-American market.

600450

600450

Add new comment