It also gives an overview of the factors taken into account when assessing the thermal safety of glazing exposed to solar radiation and offers useful guidance on how to approach this aspect of building design.

Thermal safety of glass must be taken into account early in the design of buildings, since it has implications for the specification of the glass.

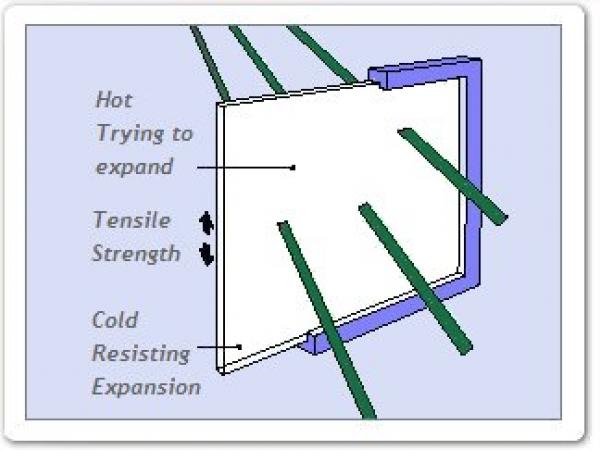

The magnitude of thermal stress depends on the temperature difference between the hottest and coldest parts of the glass and also on the distribution of the temperature across the glass. Glass is commonly glazed by retaining the edges of the glass with a gasket or glazing bead. The area of glass exposed to solar radiation absorbs heat, rises in temperature and expands. The edges of the glass, which are shielded from solar radiation, remain cooler than the exposed area. The resulting differential expansion causes tensile stress at the edge of the glass, if this exceeds the breakage strength of the glass a thermal fracture will result.

Factors affecting thermal stress

Any factor which increases the hot centre/cold edge differential tends to increase the thermal stress.The intensity of solar radiation on the glazing is determined by the geographic location of the building, the orientation of the glazing, the season, the time of day, the amount of cloud cover, atmospheric pollution and reflection from the ground or adjacent structures.

High absorption of solar radiant heat

The most important glass property in relation to thermal stress is absorption.The greater the absorption of solar radiant heat, the higher the resulting temperature of the glass will be and the greater the thermal stress.

Back-up materials

Any means by which heat is reflected or re-radiated back into the glass from inside the building increases the heat absorbed by the glass. The term back-up is used to describe a permanent structure close to the inside surface of the glass. It is usually associated with full back-up walls behind cladding, spandrel or infill panels, but it can be, for instance, a suspended ceiling, the ducts of an internal heating system, internal columns or the edge of a floor slab.

Glass edge condition

The condition of the edges of the pane of glass is extremely important. As the tensile stresses induced in the glass are located at the edges, the breakage strength of the glass is in the main related to the extent and position of flaws in the edge.

Glazing system

The edge temperatures, and therefore the thermal stresses in theglass, are related to the type and properties of the supporting system. The thermal properties of the materials (concrete, metal, wood, plastic etc.) used to frame glass vary considerably, the framing system is therefore important in determining the rate at which the glass edge will heat up. Easy paths of conduction of heat from the frame to the building structure tend to lower the edge temperature of the glass.

External shading

Partial or prolonged shading can produce large temperature differences. Additional thermal stresses will be induced in the glass if it is partially shaded from the sun by external elements, such as canopies, deep transoms, balconies, deep mullions or adjacent walls. Shadows may also be cast by more distant objects such as trees or nearby buildings.

Internal shading (from blinds or other devices)

Blinds and other internal shading devices can interfere with the free movement of air over the glass. They also reflect and re-radiate solar radiation, increasing the temperature of the glass.

Internal heaters

The primary source of energy that gives rise to thermal stressing is the sun. Secondary sources, such as convection or radiant heaters can supplement the solar heating and increase thermal stress, especially if the heat is directed onto the glass.

Insulating units

For insulating units there is reduced heat transfer across the air space. The effect is even more pronounced when further panes and air spaces are added.

High air temperatures, low rates of air movement

High air temperatures and low rates of air movement tend to reduce the rate of heat loss from the glass. Angle of the glazing (vertical or non vertical). The incidence of solar radiation varies with the angle of slope. Opening or sliding windows may become effectively double, triple or quadruple glazing when in the open position, this must be taken into account. The application of solar control films to existing windows is likely to increase the absorption of the glass and hence the thermal stress.

Other potential causes of thermal fracture

Fractures before glazing – exposure to direct sunlight

Thermal fracture can occur before the glass is glazed. Glass left stacked on site and exposed to direct sunlight may get extremely hot in the centre of the stack, even with clear glass. However, the edges are cooled by contact with the ambient air, giving rise to a temperature difference between the centre and edges of panes in the middle of the stack. Glass should always be stored out of direct sunlight.

Fractures after glazing – site conditions

During the building works, there is very often scaffolding which can give rise to static shadow. If the glass has been subjected to a thermal safety check which did not include an allowance for static shadow (because it would not occur on the finished building), then thermal breakages may occur during the construction phase. These can be avoided by fully shading the glass with loose sheeting, which is good practice for other reasons since it protects the glass surface from damage and contamination.

Fractures of inner pane of insulating units – cold climates

In cold climates, it is possible for thermal fractures to occur on the inner pane of insulating units at night. The cold temperatures cool down the framing and hence the glass edge, while the central area of the inner pane is kept warm by the room temperature.This effect can be avoided by using insulating framing materials (plastic or wood) or having correctly positioned thermal breaks in metal frames.

Assessment of Thermal Safety

The thermal safety of glass is assessed by comparing a calculated value of the maximum temperature difference the glass will encounter in its glazed situation with the safe temperature difference for the glass. If the safe temperature difference exceeds the maximum temperature difference for a particular pane of glass, then that pane will be Thermally Safe for the proposed glazing situation.

The term Thermally Safe is defined in the context of probability of failure:

- The risk of thermal stress fracture from a good, as-cut edge is sufficiently low to be acceptable

- The assessment is only valid provided the conditions at the site match those taken into account in assessing the thermal safety

If the glass is not thermally safe, then consideration will need to be given to adjusting the system or the glass type. Toughened glass has a much greater safe temperature difference than annealed or laminated glasses and consequently the solution is often to change the glass specification to a toughened form of the selected glass.

Date: 22 September 2008

600450

600450