Date: 17 November 2023

On November USGlass Magazine announced the winners of USGlass Sustainability Awards 2023, honoring specific companies and their products for their contribution to designing and creating high-performance, sustainable architecture, exhibiting efforts and actions that reduce carbon emissions and enhance environmental awareness.

As reported, now more than ever, it seems the building design, construction and facade industry is tuned in to taking action to reduce its environmental footprint. Companies and individuals actively engage in moving forward in this direction.

The USGlass Magazine editorial team carefully reviewed nominations and selected winners based on their commitments to their environmental and operational performance, along with their sustainability strategy.

The USGlass Magazine honored Satinal deep commitment in implementing high-performance sustainable solutions, recognizing its efforts both adopting green supply chain practicies and producing STRATO® EVA Carbon Free product range, a high-quality and sustainable product.

Satinal, STRATO® EVA Carbon Free product range

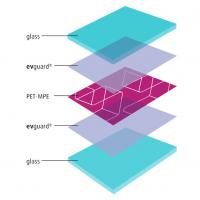

Strato® EVA Carbon Free has earned International Sustainability and Carbon Certification Plus (ISCC+), a voluntary program for industries not addressed by specific regulations but willing to certify their efforts and results in GHG Reduction. ISCC PLUS verifies that companies meet environmental standards and provides traceability along their supply chain.

Moreover, Satinal uses renewable energy 100% generated from the waters flowing from the Trentino Mountain peaks and a unique production technology that leads to no waste.

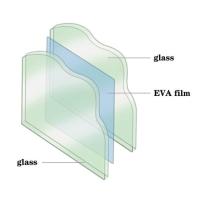

The STRATO® EVA line is completely processed in Satinal headquarters in Erba, Italy. From selected raw materials, STRATO® EVA sheets are obtained with a continuous-cycle system according to a fixed schedule program throughout the year. The product range has multiple solutions to contribute to high-performance and sustainable construction, allowing customers to use a low CO2 impact product in indoor and outdoor applications.

Satinal also offers a new generation of high-performance EVA film that uses nanoparticle technology to provide efficient solar control properties to laminated safety glass, providing significant and sustainable energy savings, energy costs and CO2 impacts on buildings and vehicles by blocking solar heat energy.

https://usg.mydigitalpublication.com/november-2023

Satinal SpA has been the first EVA film production site in Italy, a reference point in Europe for the supply of 100% made in Italy STRATO® EVA interlayers.

The application of STRATO® EVA film is a process requiring great precision for the applied temperatures and cycle times. The quality controls, which are carried out in Satinal’s R&D Lab, aim to guarantee perfect adhesion of the material to the glass surface. The deep experience acquired by Satinal in the treatment of EVA-based materials is essential to master its potential applications and fully exploit their characteristics.

Contacts:

E. info@satinal.it

S. www.satinal.it

T. +39 031 870573

600450

600450

Add new comment